Hail damage is an unavoidable reality for busy aircraft fleets and large storage facilities. Whether the resulting dents are cosmetic or safety-critical, technicians must assess them quickly and precisely. Traditional manual, hand-measured mapping methods are slow, error-prone, and can require weeks or months especially when hundreds of dents are involved.

A Real-World Example: Extreme Hail at Roswell

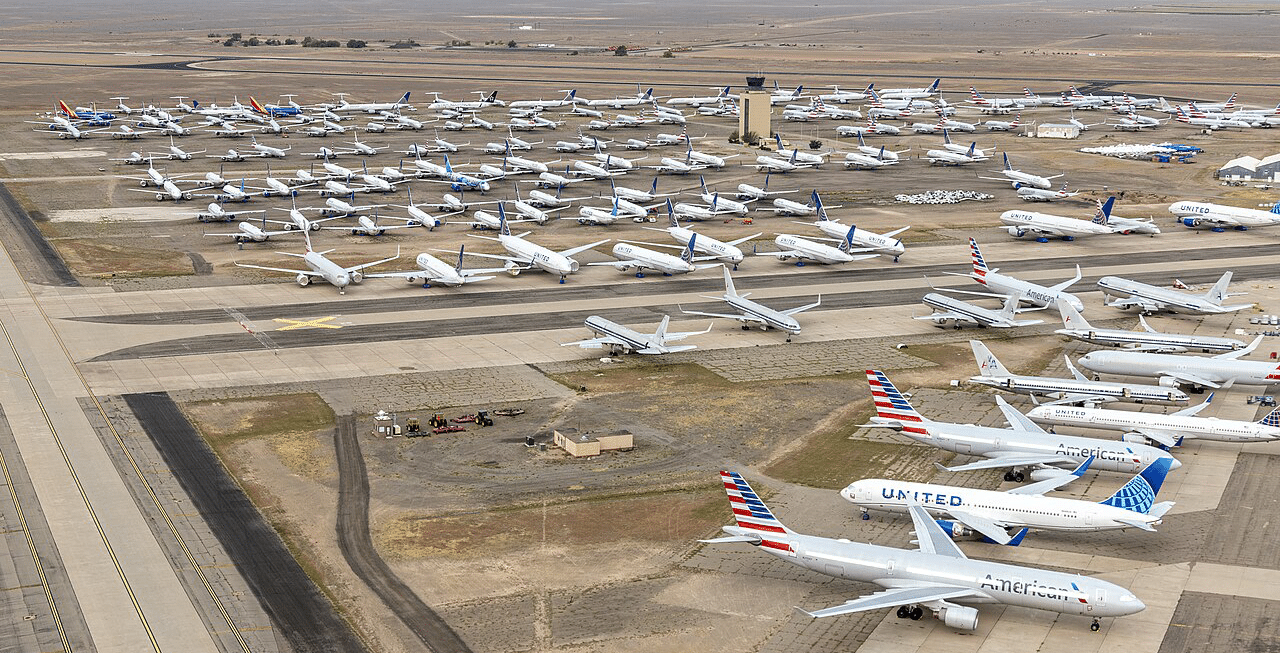

The Roswell International Air Center (RIAC) in New Mexico is a well-known aircraft storage hub, hosting up to 800 aircraft from airlines such as American, United, and Air Canada.

With no roof over its vast parking area, aircraft are fully exposed to severe weather including hailstorms capable of inflicting extensive skin damage.

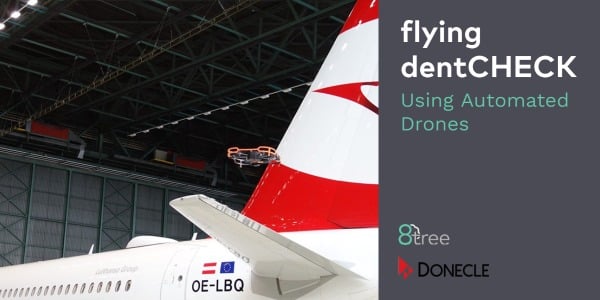

During one such extreme hail event, numerous widebody aircraft at RIAC were heavily affected. To expedite the inspection and reporting process, 8tree’s dentCHECK-as-a-Service team flew out to solve in a few days, what previously required weeks – or even months – of manual mapping.

(c) wikipedia by

How does it work? panoLite explained.

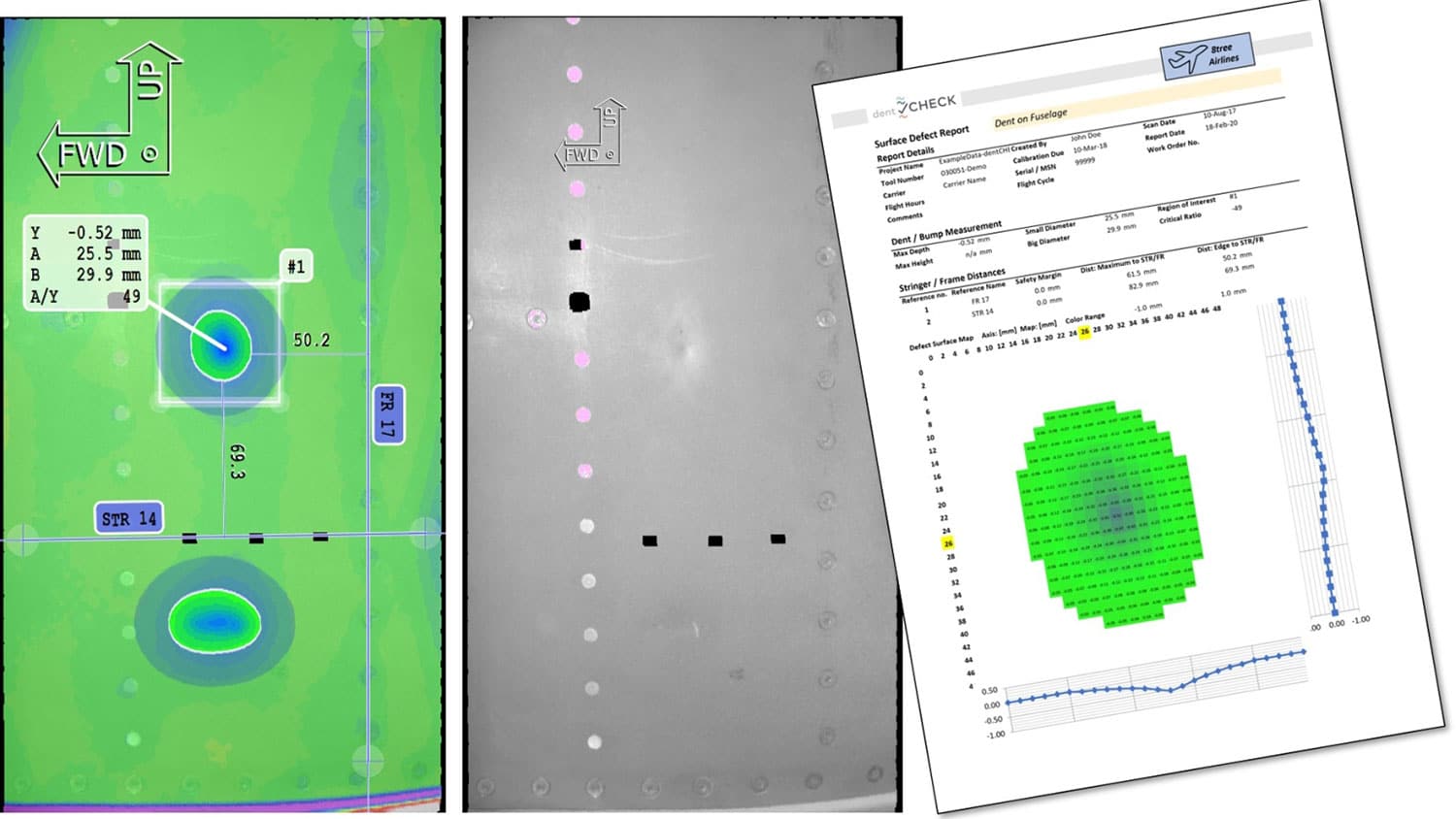

panoLite is a dentCHECK feature designed for large-area panoramic mapping. It enables operators to inspect hail-affected regions up to two meters wide. The Damage Reporting Tool (DRT) stitches multiple scans into a single, unified panoramic view.

This capability eliminates the traditional manual workflow of measuring individual dents and manually compiling reports. Instead, dentCHECK’s capabilities automate the process from start to finish.

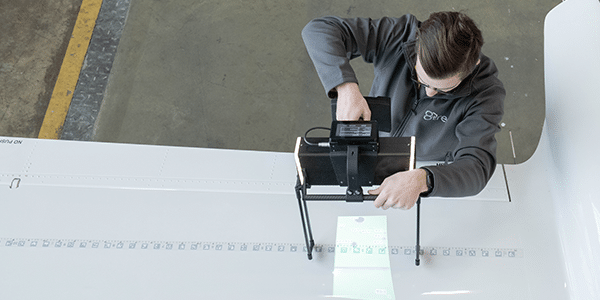

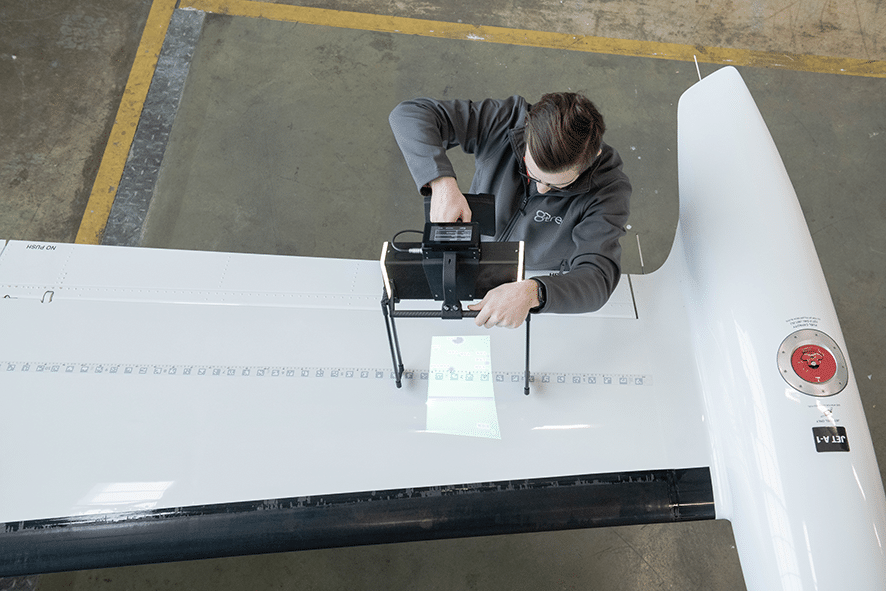

- Apply the Reusable Smart-Ruler (panoLite Tape)

Technicians place a reusable encoded panoLite tape around the damaged area. This tape serves two important functions:

- It mirrors the familiar technician workflow of marking out an area of interest.

- Its coded markers enable automatic, precise stitching of all scans in the region.

The smart-ruler applies in seconds, peels off cleanly, and can be reused repeatedly.

- Point-and-Shoot dent Mapping

With the tape in place, operators begin the standard dentCHECK point-and-shoot scanning process. As long as each scan includes at least part of the panoLite tape, dentCHECK’s Damage Reporting Tool (DRT) automatically aligns and merges all scans into one seamless panoramic map.

- Automatic Panoramic Stitching and Reporting

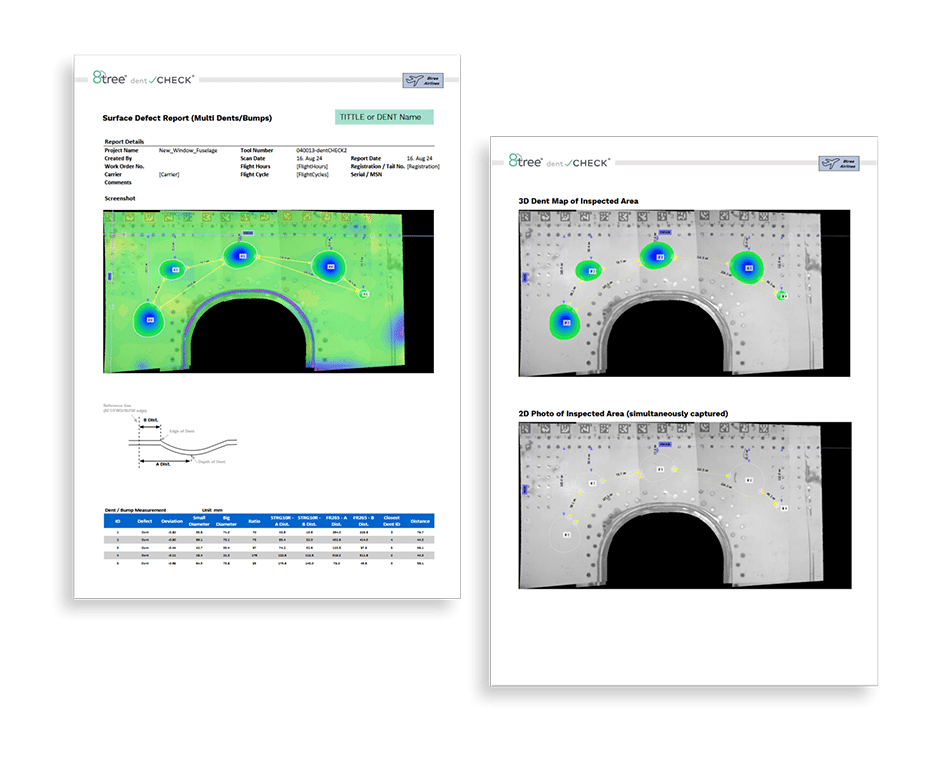

The panoLite system generates a comprehensive digital damage report within seconds. This includes:

- A large-area panorama image showing all dents

- SRM-compliant dent metrics

- Depth, size, and inter-dent distances

- Tabular and graphical summaries

- Exportable reports based on OEM templates (.xls, .pdf)

- Rapid inspection of large hail-affected areas

- High accuracy with automated stitching and measurement

- Consistent, SRM-compliant reporting

- End-to-end digital workflow—no manual measuring or data entry

- Immediate actionable results for repair planning & further NDT assessments

”What once took weeks now takes minutes.

Keith LiApplication Engineering by 8tree

A Digital Future for Hail Damage Mapping

For operators still using traditional manual methods, the transition to 8tree’s automated solution represents a major leap forward in accuracy, speed, and efficiency. Leading airlines and MROs worldwide now rely on dentCHECK and panoLite to manage catastrophic hail events at scale.

Marketing Coordinator