8tree’s dentCHECK-as-a-Service™ digitally mapped and reported hail damage on the control surfaces of B777 and A220 aircraft operated by Swiss International Air Lines.

CONSTANCE, GERMANY & RANCHO CUCAMONGA, CALIFORNIA, NOVEMBER 30, 2023

More than 1,500 dents were digitally mapped and reported by 8tree’s dentCHECK-as-a-Service (daaS) at Swiss International Air Lines (SWISS) hangars in Zurich, Switzerland. The control surfaces of a B777 and an A220 had been damaged in a hailstorm. 8tree’s service engineers used the dentCHECK dent-mapping tool to digitally map and report all dents on the affected areas, efficiently and effectively.

More than 1,500 dents were digitally mapped and reported by 8tree’s dentCHECK-as-a-Service (daaS) at Swiss International Air Lines (SWISS) hangars in Zurich, Switzerland. The control surfaces of a B777 and an A220 had been damaged in a hailstorm. 8tree’s service engineers used the dentCHECK dent-mapping tool to digitally map and report all dents on the affected areas, efficiently and effectively.

“We are very satisfied with the service provided by 8tree”, says Claus Bauer, Head of Technical Division at SWISS. “The automated dentCHECK-tool helped us to record hail damage quickly and completely so that we could rectify it promptly. This enabled us to return the aircraft concerned to flight operations in airworthy condition as quickly as possible, which is of key importance to us as an airline.”

“We are excited that Swiss International Air Lines decided to perform the dent-mapping on two hail damaged aircraft with 8tree’s service capabilities”, said Erik Klaas, CTO, 8tree. “As the first Swiss airline, they joined the growing base of dentCHECK-as-a-Service customers who disposition hail damage affected aircraft using our dentCHECK tool. We look forward to continuing Swiss International Airlines maintenance operations.”

The dentCHECK platform is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry and recognized by all major aerospace OEMs. It can also be found integrated into drones and robotic automation cells. Leading Airlines & MROs across the Commercial, Military, Cargo and Business aviation sectors use 8tree’s dentCHECK tool and 8tree’s dentCHECK-as-a-service for mapping aircraft damage and creating detailed SRM-compliant digital damage reports.

With integrated AR, dentCHECK empowers the aircraft technician with instant, actionable measurements for critical airframe damage while boosting consistency (18x), accuracy (20x), efficiency (90% time-savings) and eliminating human-subjectivity, compared to traditional manual inspection methods. dentCHECK delivers precision measurements ‘as simple as taking a photo’, and enhances safety through an improved understanding of airframe reliability.

Learn how dozens of airlines/MROs are using dentCHECK by reading our customer testimonials.

About 8tree

8tree tools, technology and services boost your production quality with precision 3D measurement that is as simple as taking a photo.

With built-in AR, 8tree’s tools empower operators of every skill-level to achieve accurate, consistent, and actionable inspection results within seconds.

For more information, visit 8-tree.com.

For recent news follow 8tree on LinkedIn.

Download Press Release as PDF

Download Press-Kit

Marketing Manager

Get in contact

LinkedIn

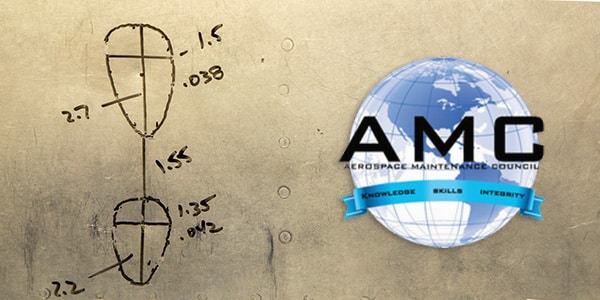

What is the Aerospace Maintenance Competition?

What is the Aerospace Maintenance Competition? How similar is the competition to a ‘real-life’ aviation maintenance industry?

How similar is the competition to a ‘real-life’ aviation maintenance industry?