Solving the chronic problems of manual surface inspection

Manual inspection of surface defects is slow, subjective, and inconsistent, leading to missed defects, costly rework, and audit risk. waveCHECK replaces uncertainty with speed, precision, and objective 3D analysis so you can analyze defects early, act with confidence, and deliver blades that meet spec every time.

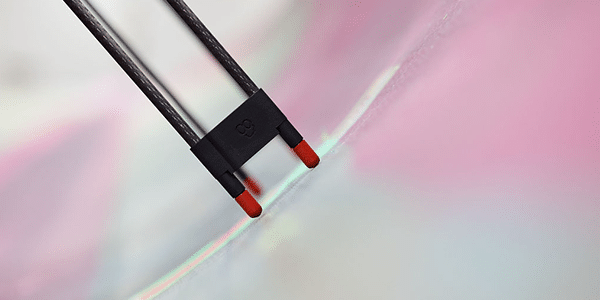

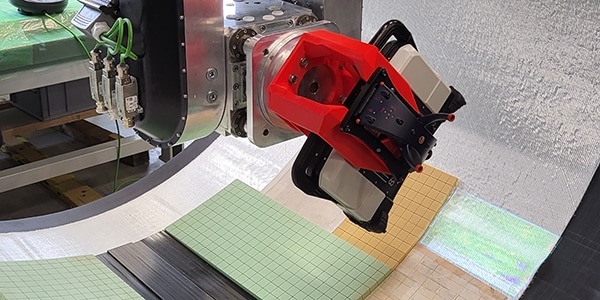

waveCHECK is a handheld-portable 3D-inspection tool for inspecting wind turbine blades in manufacturing and operation. Its efficient detection of surface defects and instant visual feedback revolutionize surface inspection.

Applications:

- Composite Waves and Wrinkles

- Steps, Height Offsets & Chamfers between core material panels and/or pre-fabricated components

- Paint & Coating Flaws

- Geometrical features, e.g. the chamfer geometry of bond line edges

- Any other surface damage that is reflected in the surface topology/topography

ISO 17025 Accredited Laboratory

- Gold standard for calibration

- Consistent precision of measurement results

- Traceable to national reference standards

Surface analysis with zero post-processing

waveCHECK’s powerful detection and instant analysis revolutionize blade inspection. The user-centric design allows for quick deployment in existing workflows: 1-Button Operation, zero Post-Processing.

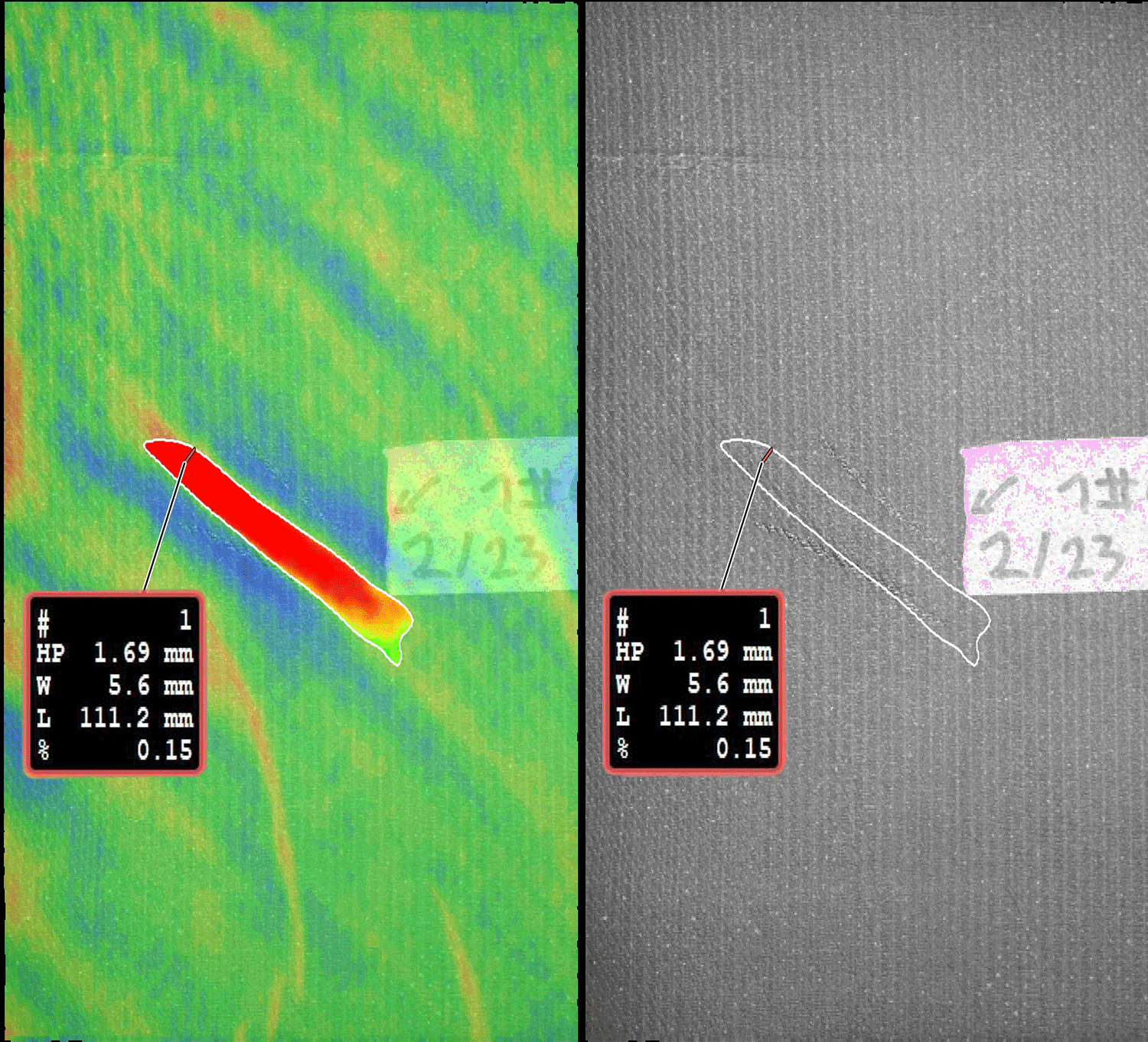

Market-proven waviness analysis with instant visual feedback

waveCHECK is a first-of-its-kind solution for end-to-end digital analysis of composite waviness. It empowers manufacturing teams to quantify composite waviness with unprecedented precision and repeatability.

Detects & displays:

- Positive, Negative and Step waves & wrinkles

- Highest point; shortest distance to edge, in main fiber direction

- Aspect ratio

- Angle of wave with respect to main fiber direction

- Works on carbon fiber and glass fiber surfaces

FAQ

What is waveCHECK and what does it do?

waveCHECK is a handheld 3D surface inspection system designed to measure and document wrinkles, steps, and surface defects on composite wind turbine blades, with sub-millimeter accuracy.

Who uses waveCHECK?

Wind turbine blade manufacturers and those involved in their operation and maintenance would greatly benefit from integrating waveCHECK in their workflow.

What types of defects can waveCHECK inspect?

waveCHECK detects and quantifies positive and negative wrinkles, step defects, and surface offsets. It also provides key measurements like wrinkle height, slope, angle relative to fiber direction, and shortest distance to edge.

Is waveCHECK suitable for both carbon fiber and glass fiber surfaces?

Yes. waveCHECK is optimized for both carbon and glass fiber composites, and works reliably on curved, bonded, or reflective surfaces commonly found in blade manufacturing.

Can waveCHECK be used at different stages of blade production?

Absolutely. waveCHECK supports inspections during post-cure, pre-bonding, or final QA stages, helping manufacturers identify defects early and avoid costly downstream repairs or scrap.

What kind of reports does waveCHECK generate?

waveCHECK provides fully digital inspection reports with visual overlays, 3D analysis, and numerical results. Reports are exportable in formats suitable for QA documentation, traceability, and audits.

Is waveCHECK calibrated in accordance with any recognised standard?

Yes. waveCHECK tools are calibrated at 8tree’s ISO 17025-accredited calibration facility, ensuring traceability to national standards, measurement confidence, and compliance with global quality standards. Calibration certificates are provided with every unit and re-calibration is recommended annually to maintain accuracy and certification integrity.

Support or training is included?

Yes. 8tree provides on-site or remote training, onboarding support, and ongoing technical assistance. We also offer calibration services and software updates to keep your waveCHECK tools inspection-ready.

8tree partners with leading Research Consortium to enhance automated Wind Blade Quality Inspection with waveCHECK®