Partnering with the Fraunhofer Institute for Wind Energy Systems (IWES), 8tree aims to revolutionize wind blade quality inspection through next-level digitalization and automation.

CONSTANCE, GERMANY, SEPTEMBER 27, 2023

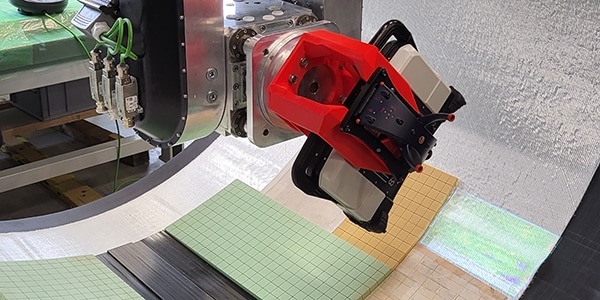

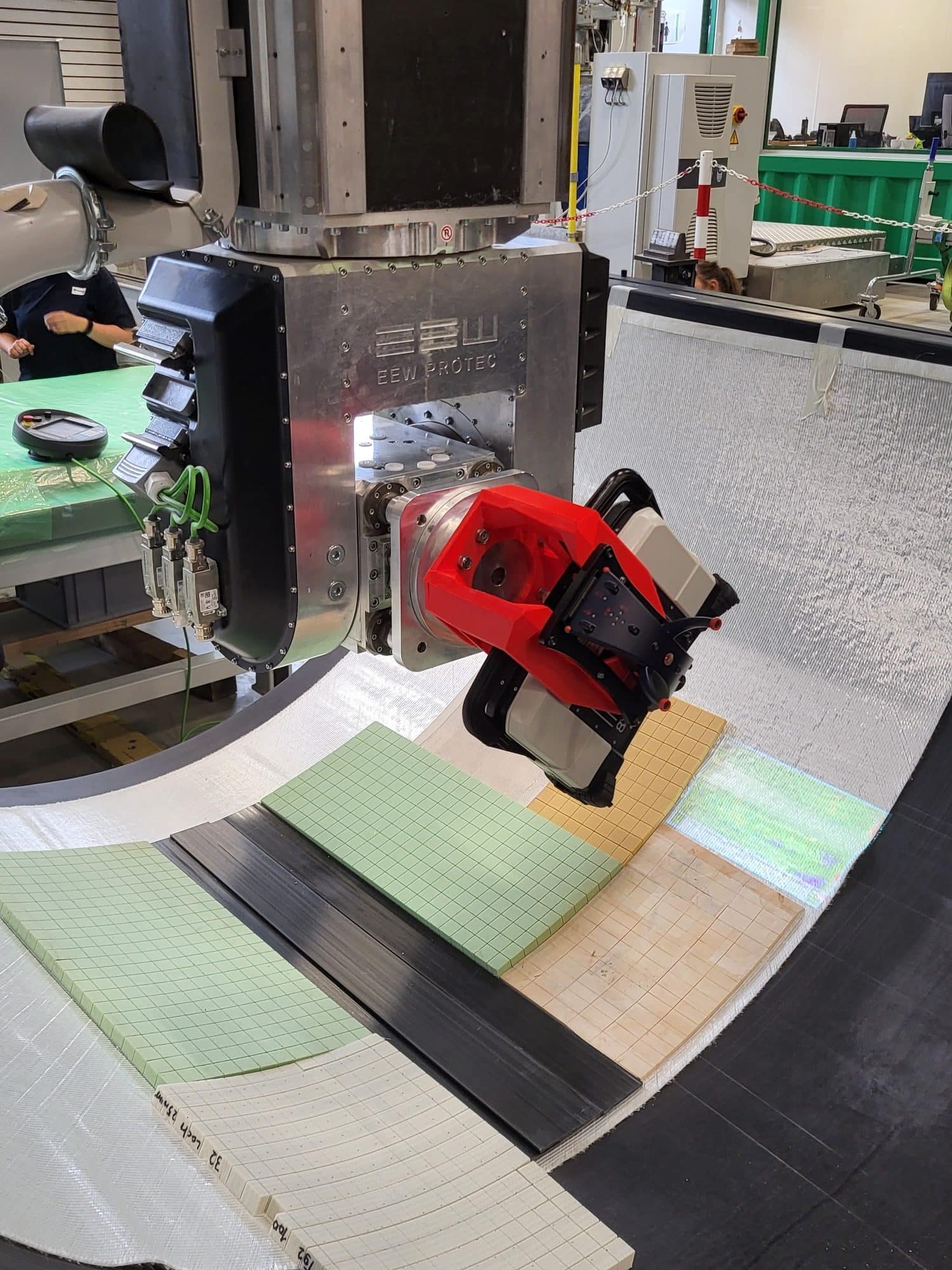

8tree, a global industry leader in 3D surface inspection tools, is proud to announce its collaboration in the “SmartRoMaIn” project led by the renowned Fraunhofer Institute for Wind Energy Systems (IWES). This initiative aims to revolutionize wind blade production by introducing a connected measurement system that detects and rectifies construction deviations early in the manufacturing process.

8tree, a global industry leader in 3D surface inspection tools, is proud to announce its collaboration in the “SmartRoMaIn” project led by the renowned Fraunhofer Institute for Wind Energy Systems (IWES). This initiative aims to revolutionize wind blade production by introducing a connected measurement system that detects and rectifies construction deviations early in the manufacturing process.

“Participating in the SmartRoMaIn project aligns seamlessly with 8tree’s commitment to delivering industry-specific 3D inspection solutions. We are thrilled to join forces with IWES and the other project partners, and look forward to contributing our expertise to enhance the production quality and efficiency of wind turbine rotor blades,” commented Erik Klaas, co-founder and CTO of 8tree.

Despite high safety margins in rotor blade production, critical construction deviations can arise during manufacturing, leading to expensive post-production adjustments. If these deviations go unnoticed, they can result in operational damages to the blades.

The “SmartRoMaIn” project aims to tackle this challenge head-on by developing a networked measurement system that promptly identifies and corrects these deviations.

Generously funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK) with a grant totaling over 1.75 million euros, the project is set to run until December 2025.

Generously funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK) with a grant totaling over 1.75 million euros, the project is set to run until December 2025.

8tree collaborates in this initiative with partners from special machinery manufacturing, laser application technologies, robotics, and digital solutions sectors. Furthermore, Wind Turbine OEMs Nordex and Vensys have joined as associated partners, underscoring the broad industry collaboration and dedication to enhancing wind blade quality inspection.“

About 8tree

8tree tools, technology and services boost your production quality with precision 3D measurement that is as simple as taking a photo.

With built-in AR, 8tree’s tools empower operators of every skill-level to achieve accurate, consistent, and actionable inspection results within seconds.

For more information, visit 8-tree.com.

For recent news follow 8tree on LinkedIn.

About Fraunhofer

About Fraunhofer IWES

About SmartRoMain