An influx of airlines and MRO specialists in North America have recently turned to digital technology for aircraft damage mapping as the industry moves into recovery.

Marketing Manager

Get in contact

LinkedIn

Marketing Manager [button open_new_tab="true" color="accent-color" hover_text_color_override="#fff" size="large" url="mailto:" text="Get in contact" color_override=""] [button open_new_tab="true" color="accent-color" hover_text_color_override="#fff" size="large" url="https://www.linkedin.com/in/ena-grzywa/" text="LinkedIn" color_override=""]

An influx of airlines and MRO specialists in North America have recently turned to digital technology for aircraft damage mapping as the industry moves into recovery.

Marketing Manager

Get in contact

LinkedIn

This press release was published on PRWeb.

dentCHECK @Horizon Air

Horizon Air, a leading regional carrier in the western US, has begun using dentCHECK to enhance the efficiency and quality of its aircraft damage-mapping and reporting activities.

“With dentCHECK, Horizon is able to quickly and accurately map dents and release aircraft back into the operation safely”, said Archie Vega, Director of Line Maintenance at Horizon Air. “dentCHECK allows us to quickly assess and map dents in a fraction of the time it would take to hand map. This will advance our capability into the future as we start to expand dentCHECK use to other Horizon maintenance locations.”

“We are delighted to welcome Horizon Air to 8tree’s growing base of dentCHECK customers”, said Arun Chhabra, CEO, 8tree. “Horizon joins the rapidly growing global aviation community of more than three dozen airlines, MROs and OEMs who rely on dentCHECK for verifiable end-to-end digital damage-mapping and reporting, across a wide variety of commercial, cargo, business and defense aircraft. We look forward to empowering Horizon’s maintenance operations and having them experience 8tree’s exceptional customer service.”

dentCHECK is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry. It is now used by the world’s leading commercial, cargo and defense MROs. Delivering real-time ‘go/no-go’ answers at the push of a single-button, the tool significantly reduces damage-mapping and reporting times, compared to traditional manual methods that use depth-gauges and straight-edges.

Approved and recognized by all major aerospace OEMs (Airbus, Boeing, Bombardier and Embraer), dentCHECK is used by the world’s leading airlines/MROs for fast and accurate damage-mapping and SRM-compliant multi-dent reporting. When compared to traditional inspection methods, dentCHECK delivers a 90% gain in efficiency and 35x better measurement consistency.

OEM-acceptance has led to widespread adoption of dentCHECK amongst airlines/MROs. Detailed case-studies from easyJet, Delta TechOps and TAP-M&E, as well as news from Lufthansa Technik, Kalitta Air, Aeromexico, Airbus’ Flightline, DHL-Express and Zeppelin, demonstrate that dentCHECK drastically reduces inspection and reporting times by up to 90%. This shortens aircraft Turn-around-Time (TaT), which further reduces lost revenues and very directly improves operational efficiency for airlines. dentCHECK enhances safety through an improved understanding of airframe reliability.

With this vision in mind, 8tree makes 3D optical surface inspection tools that solve chronic problems for multiple industries. 8tree’s products empower every operator – from mechanics on the floor, to engineers in the lab – with instantly actionable precise measurements, portability and performance. With its patented user-centric product design, instant ‘go/no-go’ answers and zero-learning curve, 8tree is committed to making precision 3D scanning more broadly accessible – technically and commercially.

For recent news follow 8tree on LinkedIn.

Horizon Air is US regional airline that operates a fleet of 62 aircraft, comprising DeHavilland Dash-8 and Embraer E175. The fleet will grow up to 71 aircraft with the addition of 9 more E175 by October 2022. Horizon serves 45 destinations across Canada and the US, and employs over 4000 employees. Horizon is part of the Alaska Airlines Group.

Marketing Manager

Get in contact

LinkedIn

In 2001, the Roswell International Air Center (RIAC) in New Mexico started to offer commercial aircraft parking. Up to 800 aircraft can be parked in a more than 5,000-acre fenced areas. American Airlines, United, Air Canada, and several others temporarily park their aircraft here. RIAC is also home to Evis Presley’s Lockheed Jetstar!

However, there is no roof over this giant open-air parking lot, which leaves the aircraft exposed to catastrophic weather events, such as hail storms.

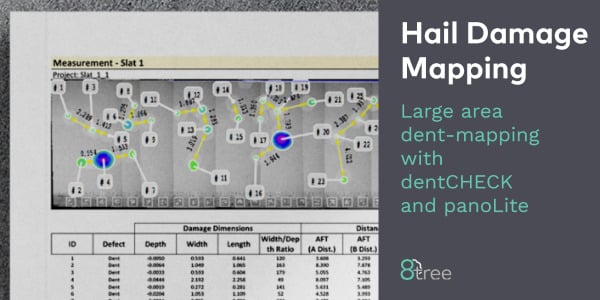

One such extreme hail-event occurred last year. Numerous aircraft at RIAC were severely damaged. 8tree’s dentCHECK was called in to expedite damage-mapping of several wide-bodies.

Taking advantage of dentCHECK’s new large area panoramic mapping functionality (“panoLite”) it took just days to map and report each aircraft, compared to the weeks or months taken by traditional methods.

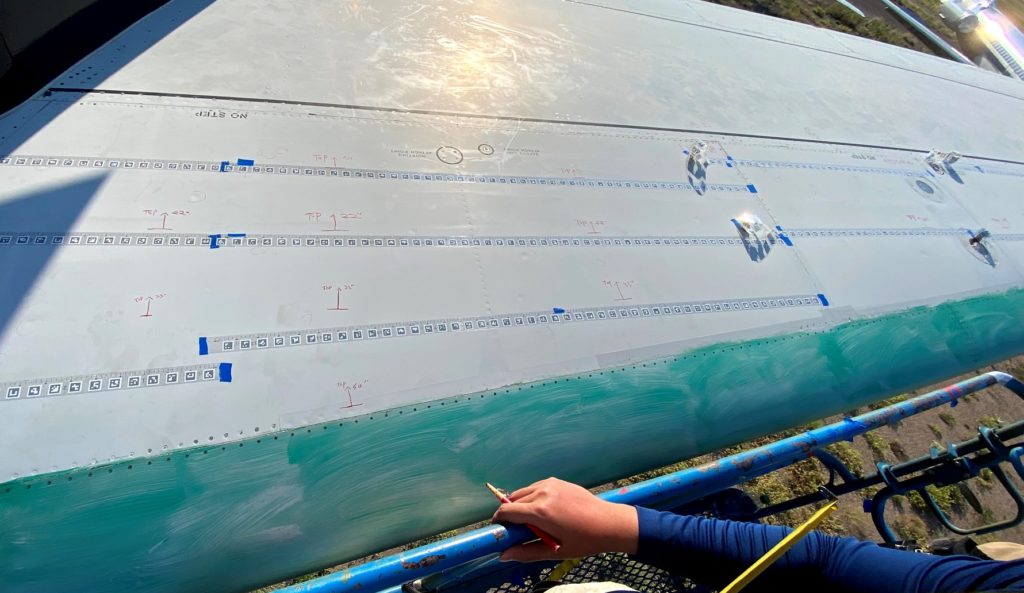

To enable the powerful panoLite capability, specially-designed and reusable ‘smart-rulers’ (panoLite tapes) are applied to outline the hail-affected areas of interest.

Applications Engineer Keith applying panoLite tapes on stabilizer.

The purpose of the panoLite smart-ruler is two-fold. First, the idea of the smart-ruler is a familiar one to aviation technicians, who currently follow an established workflow of applying masking tape marked with measurement increments to define an area of interest. Secondly, the smart-ruler is ‘smart’ and easy, as it only takes seconds to apply and peel off for re-use. Once applied, it delivers an incredibly efficient and seamless alternative to the traditional hail-mapping workflow, since it automatically communicates with the dentCHECK tool to create accurate large area damage-maps.

Once the panoLite smart-ruler has been applied, the familiar dentCHECK point-and-shoot dent mapping process can begin.

As long as some portion of the panoLite smart-ruler is visible to the dentCHECK tool during a given scan, then the well-known 8tree Damage Reporting Tool (DRT) automatically stitches the successive scans resulting in one large-area panoramic scan.

panoLite tapes applied on stabilizer to enable large area mapping of the whole area.

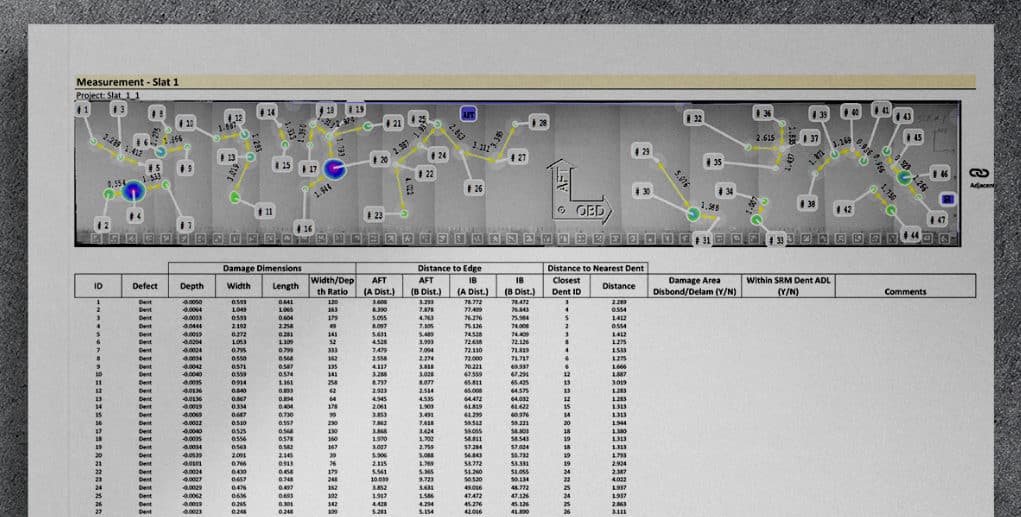

A comprehensive digital damage-report is generated as part of this automatic panoramic scan. The report format – familiar to most existing dentCHECK users – tabulates and itemizes each dent alongwith its key metrics, such as depth, size and inter-dent distance.

Part of an hail damage report (B777 – Slat).

The entire end-to-end digital process takes only a couple minutes, and equips operators and technicians with instantly-actionable damage-reports that guide informed repair strategies.

Does your organization still use slow, inaccurate and error-prone traditional manual methods to map catastrophic hail-damage?

If so, consider exploring the end-to-end digitalized dent-mapping workflow enabled by dentCHECK – a tool trusted by the leading airlines/MROs across the global aviation maintenance industry.

As for Elvis’ JetStar, after being parked for 35 years, it might not need hail damage-mapping anymore.

Marketing Manager

Get in contact

LinkedIn

This press release was published on PRWeb.

Embry-Riddle Aeronautical University, the world’s premier accredited university specializing in aviation and aerospace, has begun integrating dentCHECK into its Aviation Maintenance Science (AMS) curriculum.

Embry-Riddle’s AMS department prides itself in preparing graduates to work in all sectors of aviation and aerospace maintenance. “Part of that preparation is incorporating cutting-edge technology in our curriculum, especially when that technology is already being used by leading aviation and aerospace maintenance facilities,” said Kris Hammer, associate chair of the AMS department. “Advanced aircraft require advanced inspection methods, and 8tree’s dentCHECK is a perfect example of this type of technology. Our students getting hands-on experience with the dentCHECK equipment gives them an additional edge over graduates from other Part 147 schools.”

“This is a major step in our journey to help prepare students for the technologies and practices that await them in the aviation maintenance workplace,” said Arun Chhabra, CEO, 8tree. “By engaging the technical curiosity of today’s students, tools like dentCHECK help increase their interest in aviation maintenance careers. This strengthens their employment prospects with airlines, MROs and OEMs who already use such technologies in increasing numbers. Additionally, it addresses the industry’s chronic shortage of maintenance technicians by creating a strong pipeline of qualified candidates. We are delighted to have Embry-Riddle as the launch partner for 8tree’s Academic Initiative in the aviation industry, and look forward to helping the industry navigate the ongoing generational transition in the workforce.”

dentCHECK is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry. It is now used by the world’s leading commercial, cargo and defense MROs. Delivering real-time ‘go/no-go’ answers at the push of a single-button, the tool significantly reduces damage-mapping and reporting times, compared to traditional manual methods that use depth-gauges and straight-edges.

Approved and recognized by all major aerospace OEMs (Airbus, Boeing, Bombardier and Embraer), dentCHECK is used by the world’s leading airlines/MROs for fast and accurate damage-mapping and SRM-compliant multi-dent reporting. When compared to traditional inspection methods, dentCHECK delivers a 90% gain in efficiency and 35x better measurement consistency.

OEM-acceptance has led to widespread adoption of dentCHECK amongst airlines/MROs. Detailed case-studies from easyJet, Delta TechOps and TAP-M&E, as well as news from Lufthansa Technik, Kalitta Air, Aeromexico, Airbus’ Flightline, DHL-Express and Zeppelin, demonstrate that dentCHECK drastically reduces inspection and reporting times by up to 90%. This shortens aircraft Turn-aroundTime (TaT), which further reduces lost revenues and very directly improves operational efficiency for airlines. dentCHECK enhances safety through an improved understanding of airframe reliability.

With this vision in mind, 8tree makes 3D optical surface inspection tools that solve chronic problems for multiple industries. 8tree’s products empower every operator – from mechanics on the floor, to engineers in the lab – with instantly actionable precise measurements, portability and performance. With its patented usercentric product design, instant ‘go/no-go’ answers and zero-learning curve, 8tree is committed to making precision 3D scanning more broadly accessible – technically and commercially.

For recent news follow 8tree on LinkedIn.

Reporters worldwide contact Embry-Riddle Aeronautical University for content experts in all aspects of aviation, aviation business, aerospace, engineering and STEM-related fields. Our faculty experts specialize in unmanned and autonomous systems, security and intelligence, air traffic and airport management, astronomy, human factors psychology, meteorology, spaceflight operations, urban air mobility and much more. Visit the Embry-Riddle Newsroom for story ideas.

Embry-Riddle educates 32,500+ students at its residential campuses in Daytona Beach, Florida and Prescott, Arizona, at approximately 110 Worldwide Campus locations and

through online degree programs. U.S. News & World Report has named Embry-Riddle Worldwide the nation’s No. 1 provider of online bachelor’s degree programs.

For more information, visit https://erau.edu/

Aviation Maintenance Science information https://erau.edu/ams

Marketing Manager

Get in contact

LinkedIn

Check out this feature by MRO Business Today discussing the implications of the pandemic on the aircraft maintenance industry.

Marketing Manager

Get in contact

LinkedIn

This press release was published on PRWeb.

KF Aerospace, a leading Canadian approved maintenance organization (AMO) has begun using 8tree’s dentCHECK to enhance the efficiency and quality of its dent-mapping activities.

“KF performs hundreds of structural repairs annually on a wide variety of commercial aircraft” says Gregg Evjen, Chief Operating Officer, “Implementation of dentCHECK has allowed KF to improve accuracy, accelerate the damage mapping processes, and produce a digital record for our Engineers to utilize as they develop the repairs.”

“We are absolutely thrilled that KF Aero decided on dentCHECK, when they embraced the tool after a rigorous evaluation a couple years ago”, said Arun Chhabra, CEO, 8tree. “They joined the global community of dentCHECK users as the first Canadian firm to do so. Several other Canadian operators have since followed in their footsteps. KF Aero joins the ranks of more than three dozen MROs, airlines and OEMs that use dentCHECK daily to disposition dent-damage on aircraft across the cargo, commercial, business and defense aviation sectors. We look forward to continuing to support KF Aero’s maintenance operations and having them experience 8tree’s exceptional customer service.”

dentCHECK is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry. It is now used by the world’s leading commercial, cargo and defense MROs. Delivering real-time ‘go/no-go’ answers at the push of a single-button, the tool significantly reduces damage-mapping and reporting times, compared to traditional manual methods that use depth-gauges and straight-edges.

Approved and recognized by all major aerospace OEMs (Airbus, Boeing, Bombardier and Embraer), dentCHECK is used by the world’s leading airlines/MROs for fast and accurate damage-mapping and SRM-compliant multi-dent reporting. When compared to traditional inspection methods, dentCHECK delivers a 90% gain in efficiency and 35x better measurement consistency.

OEM-acceptance has led to widespread adoption of dentCHECK amongst airlines/MROs. Detailed case-studies from easyJet, Delta TechOps and TAP-M&E, as well as news from Aeromexico, Airbus’ Flightline, DHL-Express and Zeppelin, demonstrate that dentCHECK drastically reduces inspection and reporting times by up to 90%. This shortens aircraft Turn-around-Time (TaT), which further reduces lost revenues and very directly improves operational efficiency for airlines. dentCHECK enhances safety through an improved understanding of airframe reliability.

With this vision in mind, 8tree makes 3D optical surface inspection tools that solve chronic problems for multiple industries. 8tree’s products empower every operator – from mechanics on the floor, to engineers in the lab – with instantly actionable precise measurements, portability and performance. With its patented user-centric product design, instant ‘go/no-go’ answers and zero-learning curve, 8tree is committed to making precision 3D scanning more broadly accessible – technically and commercially.

For recent news follow 8tree on LinkedIn.

We’re all about THE CRAFT.

KF Aerospace celebrates 50 years of innovative aircraft solutions for corporate, commercial and military customers worldwide—including major airlines like WestJet, Air Canada, Icelandair and Condor. From our humble roots in the Okanagan Valley, KF has grown to specialize in aircraft maintenance and modifications, military aircrew training, air cargo operations and leasing—with the same commitment to quality and service established by our founder in 1970. With facilities across Canada, KF is home to around 1000 highly skilled employees.

To learn more visit http://www.kfaero.ca

Marketing Manager

Get in contact

LinkedIn

This press release was published on PRWeb.

Kalitta Air, a leading US cargo and special-missions airline has begun using 8tree’s dentCHECK to enhance the efficiency and quality of its dent-mapping activities. dentCHECK is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry. It is now used by the world’s leading commercial, cargo and defense MROs. Delivering real-time ‘go/no-go’ answers at the push of a single-button, the tool significantly reduces damage-mapping and reporting times, compared to traditional manual methods that use depth-gauges and straight-edges.

“With the implementation of 8tree’s dentCHECK technology, Kalitta Air’s dent mapping program will be elevated to the next level. We look forward to working with 8tree in implementing this state-of-the-art technology”, said Zoltan Kocis, Vice President of Maintenance, Engineering and Procurement, Kalitta Air.

“We are delighted to welcome Kalitta Air to the rapidly growing global community of dentCHECK users”, said Arun Chhabra, CEO, 8tree. “Kalitta Air joins the ranks of more than three dozen MROs, airlines and OEMs that use dentCHECK daily to disposition dent-damage on aircraft across the cargo, commercial, business and defense aviation sectors. We look forward to supporting Kalitta Air’s maintenance operations and having them experience 8tree’s exceptional customer service.”

dentCHECK is approved and recognized by all major aerospace OEMs (Airbus, Boeing, Bombardier and Embraer) and used by the world’s leading airlines/MROs for fast and accurate damage-mapping and SRM-compliant multi-dent reporting. When compared to traditional inspection methods, dentCHECK delivers a 90% gain in efficiency and 37x better measurement consistency.

OEM-acceptance has led to widespread adoption of dentCHECK amongst airlines/MROs. Detailed case-studies from easyJet, Delta TechOps and TAP-M&E, as well as news from Aeromexico, Airbus’ Flightline, DHL-Express and Zeppelin, demonstrate that dentCHECK drastically reduces inspection and reporting times by up to 90%. This shortens aircraft Turn-around-Time (TaT), which further reduces lost revenues and very directly improves operational efficiency for airlines. dentCHECK enhances safety through an improved understanding of airframe reliability.

With this vision in mind, 8tree makes 3D optical surface inspection tools that solve chronic problems for multiple industries. 8tree’s products empower every operator – from mechanics on the floor, to engineers in the lab – with instantly actionable precise measurements, portability and performance. With its patented user-centric product design, instant ‘go/no-go’ answers and zero-learning curve, 8tree is committed to making precision 3D scanning more broadly accessible – technically and commercially.

For recent news follow 8tree on LinkedIn.

Kalitta Air is an FAR Part 121 Air Carrier and a leading provider of air cargo transportation, scheduled and on-demand charter service for customers in the United States and around the world. The company operates an all-Boeing fleet of 38 aircraft comprising the 747, 767 and 777 aircraft types. Kalitta Maintenance operates a maintenance, repair and overhaul facility at Oscoda-Wurtsmith Airport in Michigan. Kalitta Air makes it happen – on time, anytime, anywhere.

Marketing Manager

Get in contact

LinkedIn

This press release was published on PRWeb.

The focus of this program was to develop an integrated solution comprising dentCHECK – 8tree’s 3D dent-mapping technology – onboard a Donecle drone, to enable automatic inspection of aircraft surfaces.

Tested on metallic and composite surfaces, this integrated ‘flying dentCHECK’ solution allows the comparison of new inspection results against the aircraft’s digital damage record.

The collaborative project was able to validate the technology at the French military base 118 in Mont-de-Marsan. Within one hour, the flying dentCHECK inspected dents and bumps of an entire Rafale fighter with accuracy of 0.1mm depth and 2mm size.

“It’s all about automating non-destructive testing tasks and procedures. The 100% automated flying dentCHECK drastically reduces the time taken to inspect an aircraft while improving the quality of maintenance operations significantly.”, says Erik Klaas, 8tree’s CTO.

Both 8tree and Donecle will be exhibiting at MRO Europe in Amsterdam, October 19-21. The flying dentCHECK will be showcased at Donecle’s booth #3080C, while 8tree will be demonstrating the latest dentCHECK features at booth #9059.

“We make precision 3D measurement as simple as taking a photo”

With this vision in mind, 8tree makes 3D optical surface inspection tools that solve chronic problems for multiple industries. 8tree’s products empower every operator – from mechanics on the floor, to engineers in the lab – with instantly actionable precise measurements, portability and performance. With its patented user-centric product design, instant ‘go/no-go’ answers and zero-learning curve, 8tree is committed to making precision 3D scanning more broadly accessible – technically and commercially.

For recent news follow 8tree on LinkedIn.

Press release initially published here —

English Version

German Version

Marketing Manager

Get in contact

LinkedIn

Check out this interview with Arun Chhabra in the MRO Business Today Magazine (Sep Issue) on page 16.

Read an excerpt on the right or head over to the full-length interview attached.

Link to Magazine (article on p.16)

Download PDF (article only)

Marketing Manager

Get in contact

LinkedIn

Aircraft maintenance requires regular inspection of the aircraft surfaces. We are speaking about non-destructive testing (NDT). These tasks are time-consuming and potentially dangerous for operators working at height. The Defense Innovation Agency (DIA) and other stakeholders called for projects to “automate non-destructive testing“. The project aims to develop solutions to reduce the duration and improve the quality of such maintenance operations.

8tree’s collaboration with Donecle and Dassault to develop a flying dentCHECK is part of this initiative. The French Ministry of Defense recently announced an article and a video about our drone project with Donecle and 8tree.

The article was published in French. Read below a segment about our project and have a look at the video, where you can see the drone flying around a Rafale aircraft.

DONECLE, in partnership with 8tree and Dassault provides an automatic 3D inspection of aircraft skin, thanks to a 100% automated drone. This technique allows to detect and measure surface defects such as dents, impacts, or perforations. Tested on metallic and composite surfaces, the solution also allows comparisons with the aircraft’s digital mapping and digital monitoring of the evolution of defects.

– Source

Marketing Manager

Get in contact

LinkedIn