CONSTANCE, GERMANY & RANCHO CUCAMONGA, CALIFORNIA – January 20, 2026.

8tree’s cofounding owners, Erik Klaas and Arun Chhabra, have appointed Pia Böttcher and Leonard Buck as Managing Directors of 8tree Germany, further expanding its leadership team to support the company’s long-term growth trajectory and customer success in Europe.

Pia Böttcher will continue to lead 8tree’s operational excellence as COO. “I am thankful for the continued trust and looking forward to contributing to further growth,” said Pia Böttcher, COO and Managing Director of 8tree Germany.

Leonard Buck will oversee 8tree’s commercial strategy, and customer engagement, to advance the company’s mission of delivering fast, intuitive, and precise 3D surface inspection solutions.

”I am excited to contribute to 8tree’s growth trajectory in this new role during such a dynamic time. 8tree’s innovative approach to 3D measurement transforms how operators achieve quality and efficiency. I look forward to building on this momentum and driving global customer success."

Leonard BuckManaging Director at 8tree Germany

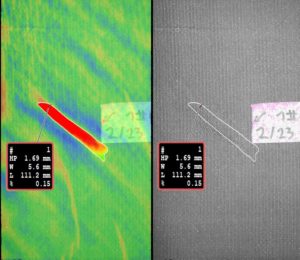

”Our appointment of Pia and Leo underscores 8tree’s commitment to strengthening support and enhancing value for its growing customer base in the aerospace, MRO, and wind-turbine blade manufacturing industries".

Erik Klaas | Arun ChhabraCTO | CEO

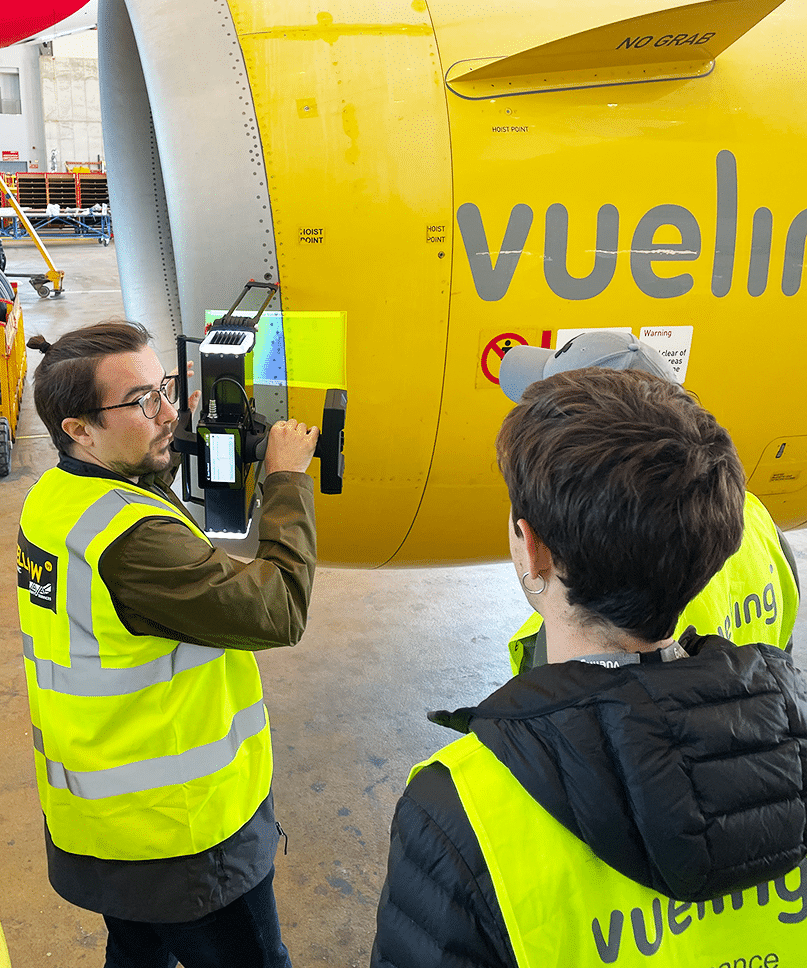

The expansion of 8tree’s management team reflects the company’s continued investment in global leadership and its focus on enabling customers to achieve faster, more reliable inspections through easy-to-use, augmented-reality-based measurement tools.

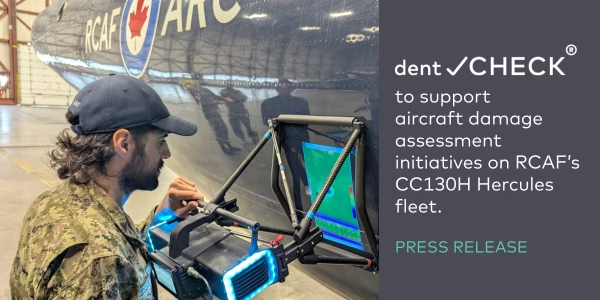

Learn how dozens of airlines/MROs are using dentCHECK by reading our customer testimonials.

About 8tree

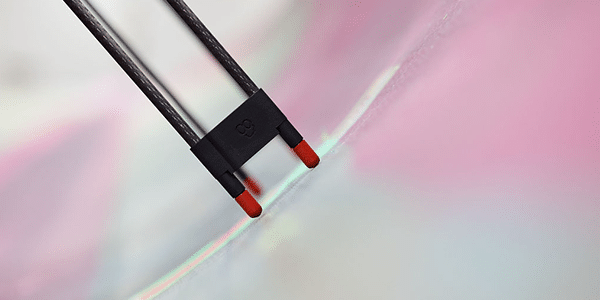

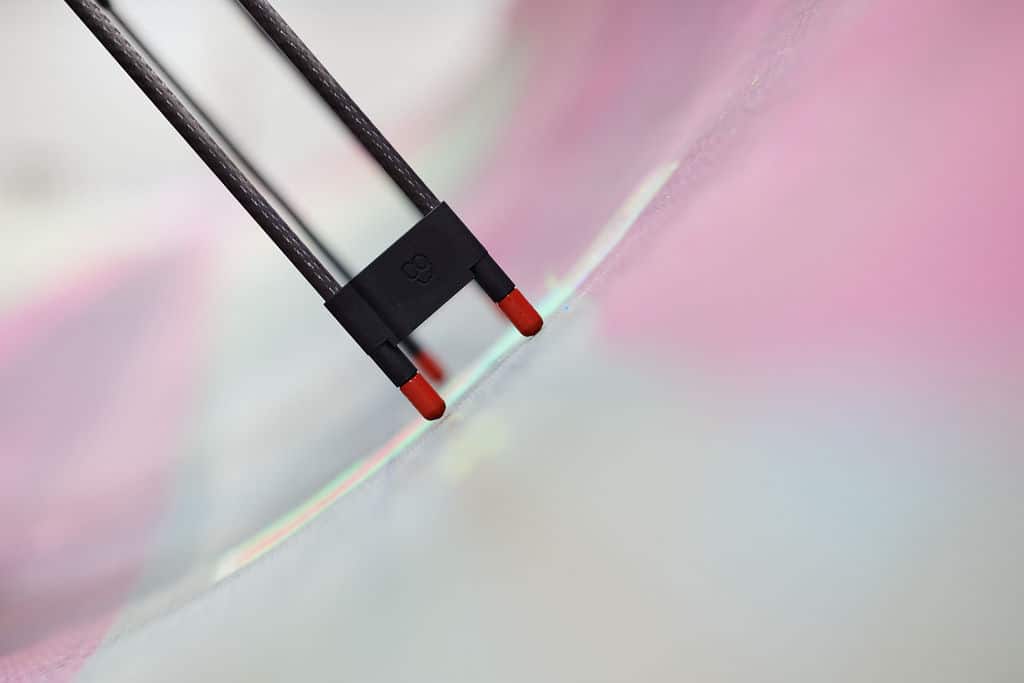

8tree tools, technology and services boost your production quality with precision 3D measurement that is as simple as taking a photo.

With built-in AR, 8tree’s tools empower operators of every skill-level to achieve accurate, consistent, and actionable inspection results within seconds.

For more information, visit 8-tree.com

For recent news, follow 8tree on LinkedIn

Marketing Coordinator