Wind turbine blades are primarily manufactured from fiber-reinforced composites (FRP). While this material is lightweight and strong, it is prone to local manufacturing defects, including waviness and wrinkles in the laminate.

Even small wrinkles can significantly reduce structural integrity and ultimately lead to costly repairs or premature blade failure. With the growing emphasis on blade quality at delivery and an increasing number of warranty claims which cost manufacturers and operators millions of dollars, the pressure to identify and prevent wrinkles has never been greater.

Primary Causes of Wrinkles in Wind Blades

1. Material Draping & Layup Errors

During manual layup, even slight misalignments can leave fibers uneven. When resin cures, these imperfections form permanent wrinkles. Complex shapes such as edges, radii, and transitions are particularly prone to misaligned fiber placement.

2. Vacuum Infusion & Resin Flow

Vacuum infusion requires consistent pressure. Poor vacuum bagging or bridging can prevent full compaction, allowing fibers to lift and form waves. Uneven resin flow may also shift fibers, creating localized thickness variations and wrinkling.

3. Core Material Gaps

Sandwich blade structures often use polymer foam or balsa wood cores. Gaps or misfits between core pieces can create misalignments of the fibers layed-up. After curing, these irregularities manifest as laminate undulations, and local laminate waviness.

4. Thermal Effects

During curing, resins undergo an exothermic reaction, generating heat. If temperature control is poor, uneven expansion or shrinkage can distort the laminate. Localized hot spots can amplify the risk of wrinkle formation.

Why Wrinkles Are Dangerous

Fibers in composites achieve their highest strength when perfectly aligned in straight lines. Wrinkles bend or misdirect the stress flow, introducing out-of-plane stresses. This reduces the load-carrying capacity, accelerates fatigue, and increases the risk of delamination or sudden fracture.

Prevention and Detection

Reducing the occurrence of wrinkles requires both process control and inspection discipline.

Prevention best practices include:

- Ensuring proper fabric layup techniques

- Maintaining adequate compaction and bagging procedures

- Reducing gaps in core materials

- Carefully managing resin flow and cure temperature

Detection methods include:

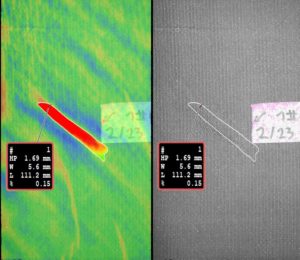

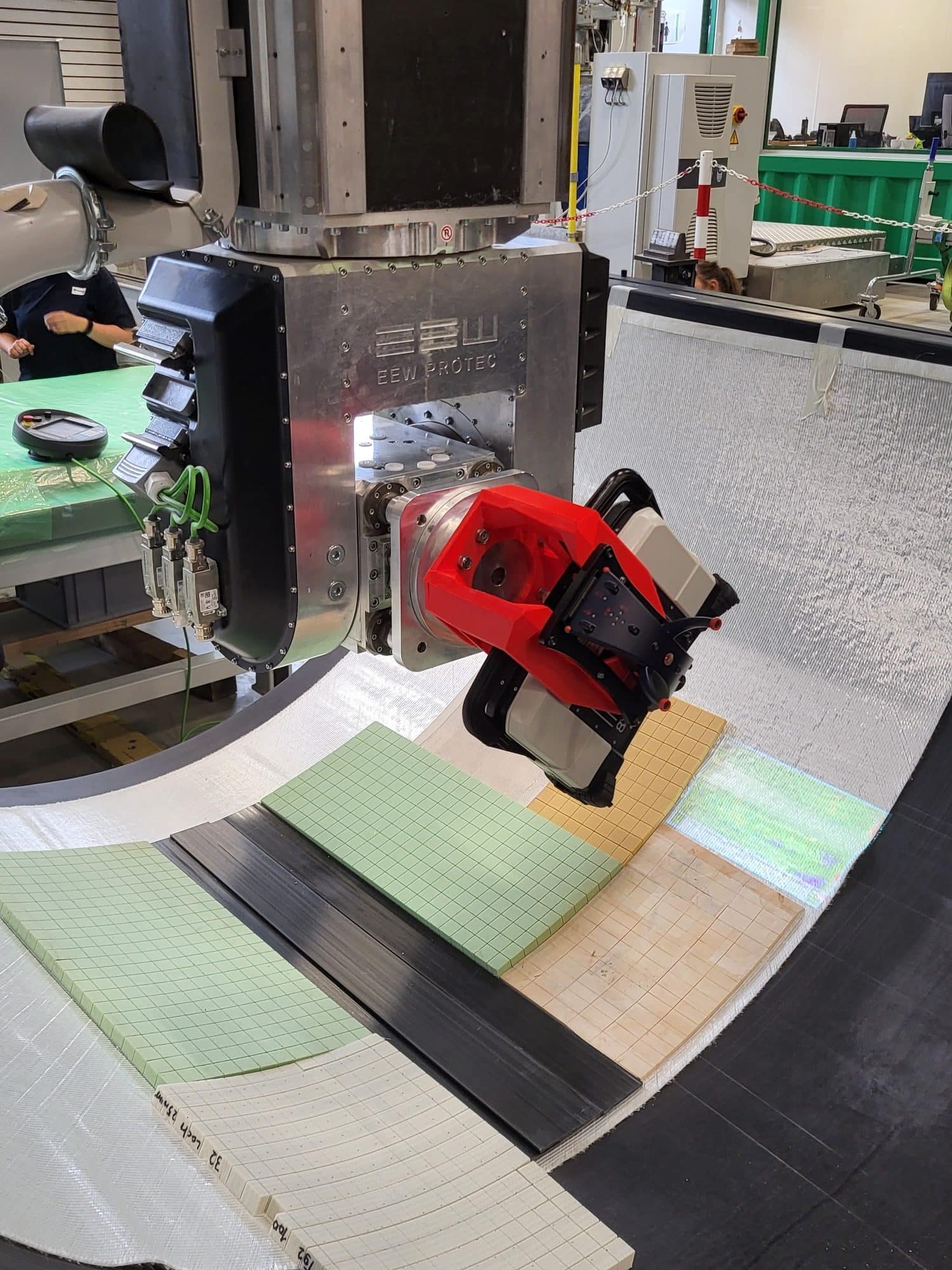

- Non-destructive testing (NDT) such as ultrasound and thermography

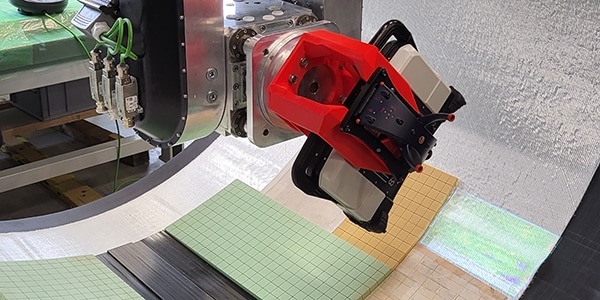

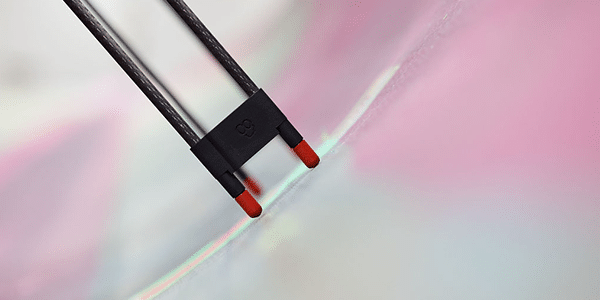

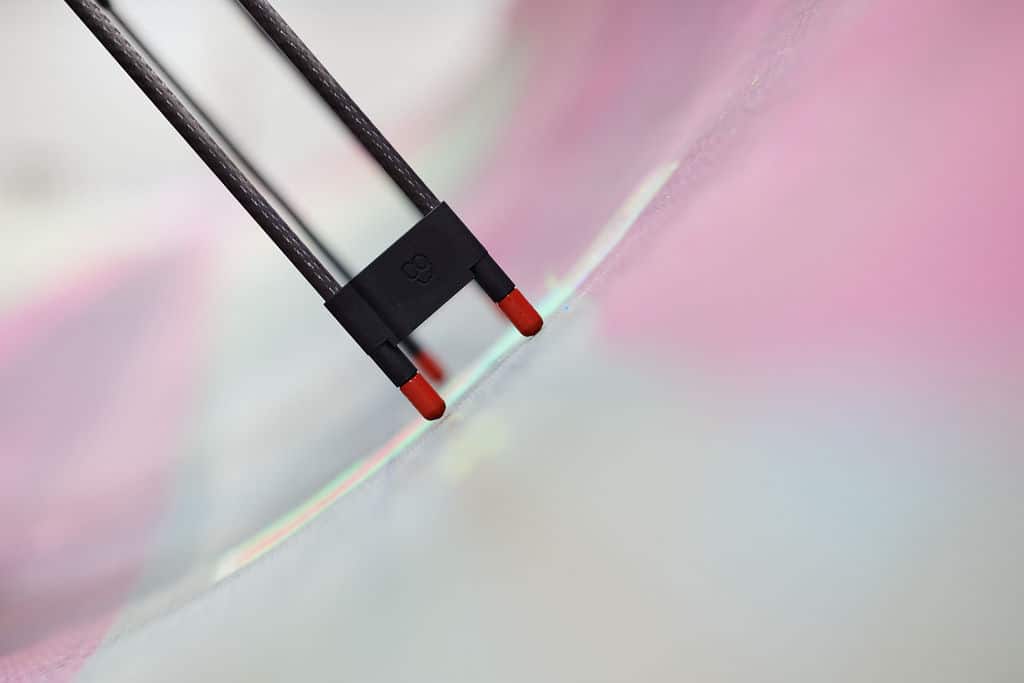

- Digital 3D inspection tools such as 8tree’s waveCHECK, which provides instant, repeatable wrinkle and surface quality measurements

waveCHECK can be used directly on the blade surface to inspect and analyze surface defects such as wrinkles and waviness

Conclusion

Wrinkles in wind turbine blades are not just cosmetic issues because they pose serious risks to structural integrity and long-term blade performance. By understanding the causes, recognizing the risks, and implementing robust prevention and detection techniques, manufacturers and operators can protect turbine reliability while minimizing costly warranty claims and repairs.