8tree expands service offer and strengthens presence in line maintenance by partnering with Panasonic Avionics

This press release was published on PRWeb.

Panasonic Avionics Corporation (Panasonic) and 8tree today announced a partnership to make available the dentCHECK dent-mapping/reporting service at select Panasonic Technical Services (PTS) regional line stations: Los Angeles International Airport (LAX), London Heathrow (LHR) and Sydney Kingsford Smith Airport (SYD).

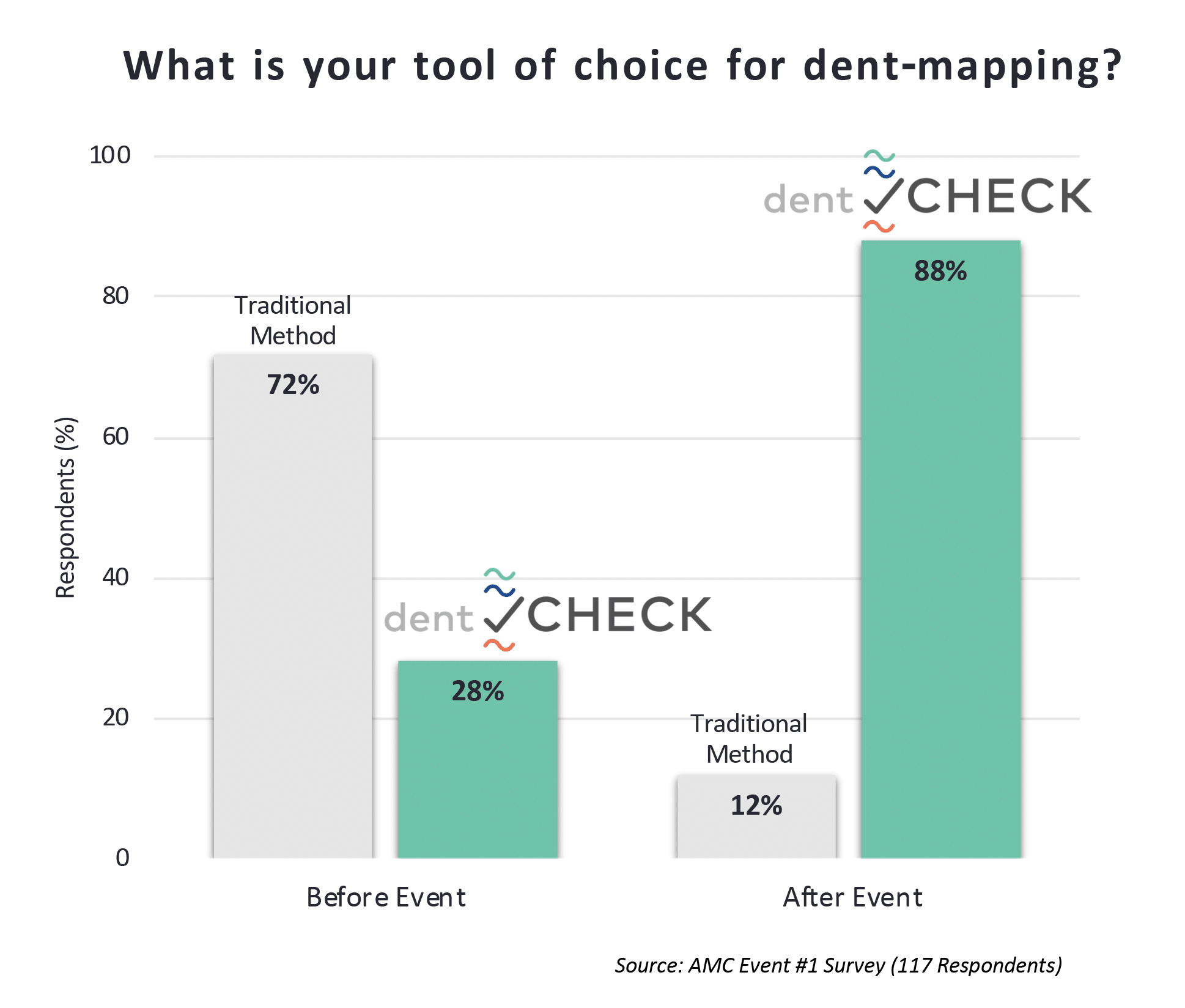

This new service offering will allow Panasonic Avionics customers yet another convenient, accurate and efficient way to protect their commercial aircraft investment, avoiding unnecessary cost and time delays. Further, the service will complement PTS’s existing line of best-in-class products and services, continuing its history of being a premier service solution provider.

Now available — dentCHECK dent-mapping/reporting service at select Panasonic Technical Services (PTS) regional line stations: (LAX), (LHR) and (SYD).

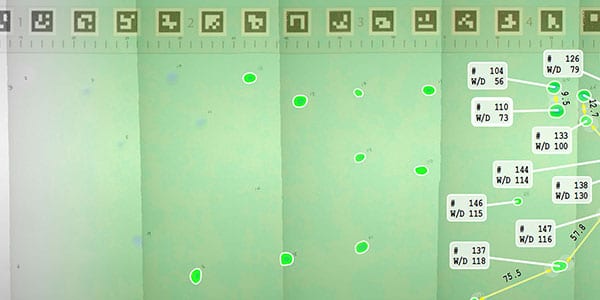

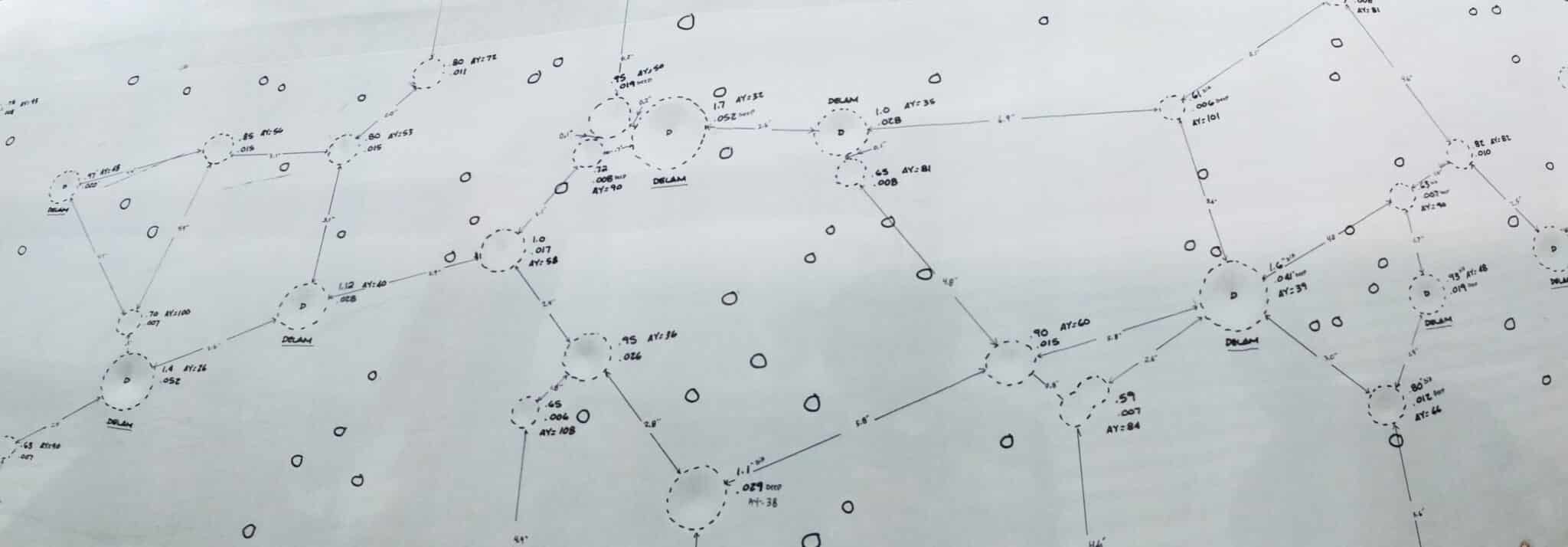

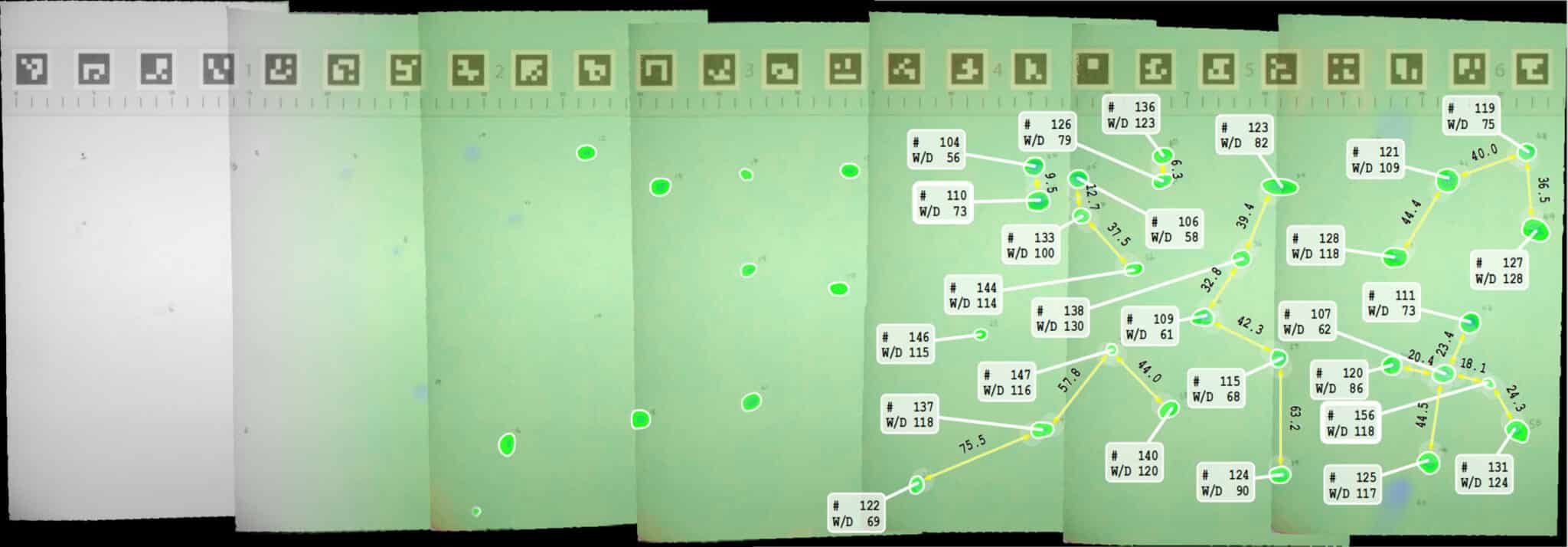

“We are excited to embark on this partnership with Panasonic Avionics, driven by a common goal – to deliver accurate and objective dent-mapping reports that lead to quicker turn-around-times for line maintenance operations worldwide”, said Arun Chhabra, CEO of 8tree. “This will be possible by leveraging Panasonic’s strong global line-support footprint, coupled with the proven track-record of 8tree’s dentCHECK tool in aviation maintenance.”

About Panasonic Avionics Corporation

Panasonic Avionics Corporation is the world’s leading supplier of Inflight Entertainment and Communication (IFEC) systems. The company’s best-in-class solutions, supported by professional maintenance services, fully integrate with the cabin enabling its customers to deliver the ultimate travel experiences with a rich variety of entertainment choices, resulting in improved quality communication systems and solutions, reduced time-to-market and lower overall costs.

Established in 1979, Panasonic Avionics Corporation, a U.S. corporation, is a subsidiary of Panasonic Corporation of North America, the principal North American subsidiary of Panasonic Corporation. Headquartered in Lake Forest, California with operations in 80 global locations, it has delivered over 14,300 IFE systems and 2,200 inflight connectivity solutions to the world’s leading airlines.

For additional information, please visit http://www.panasonic.aero

About 8tree

“We make precision 3d measurement as simple as taking a photo”

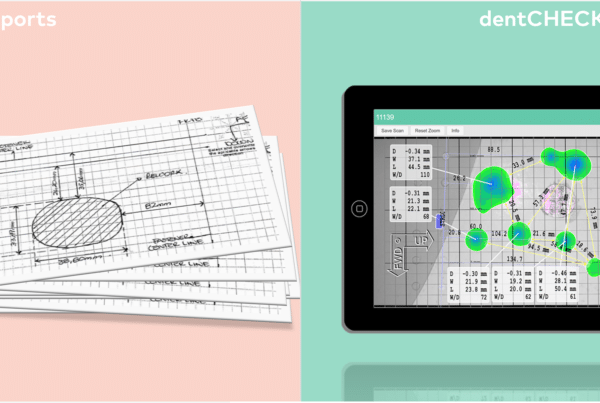

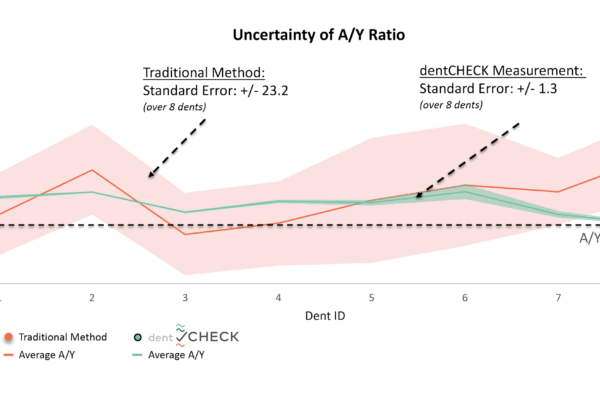

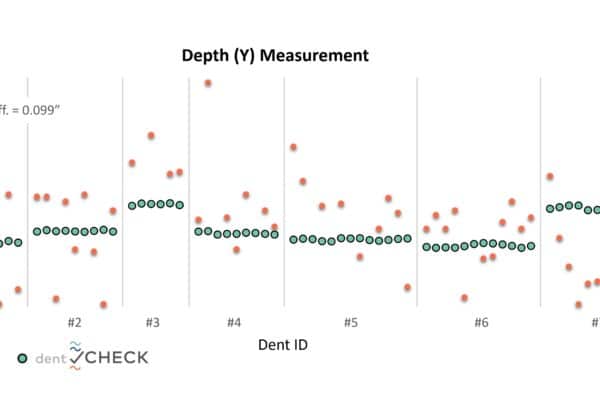

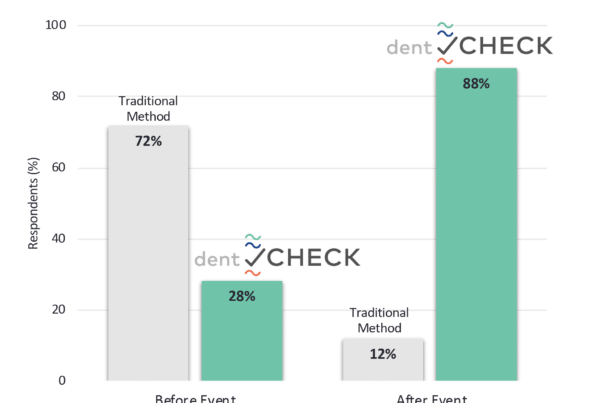

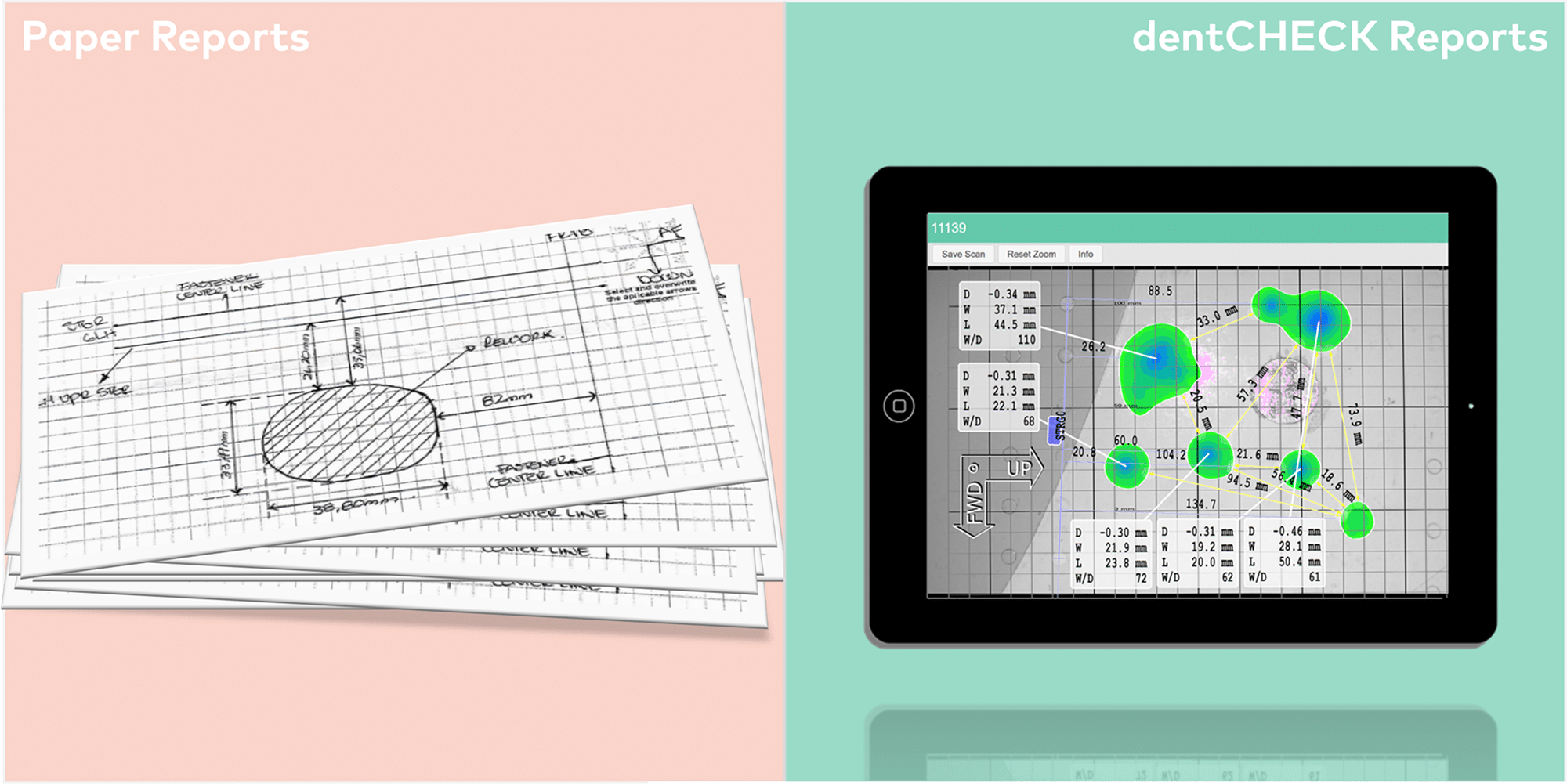

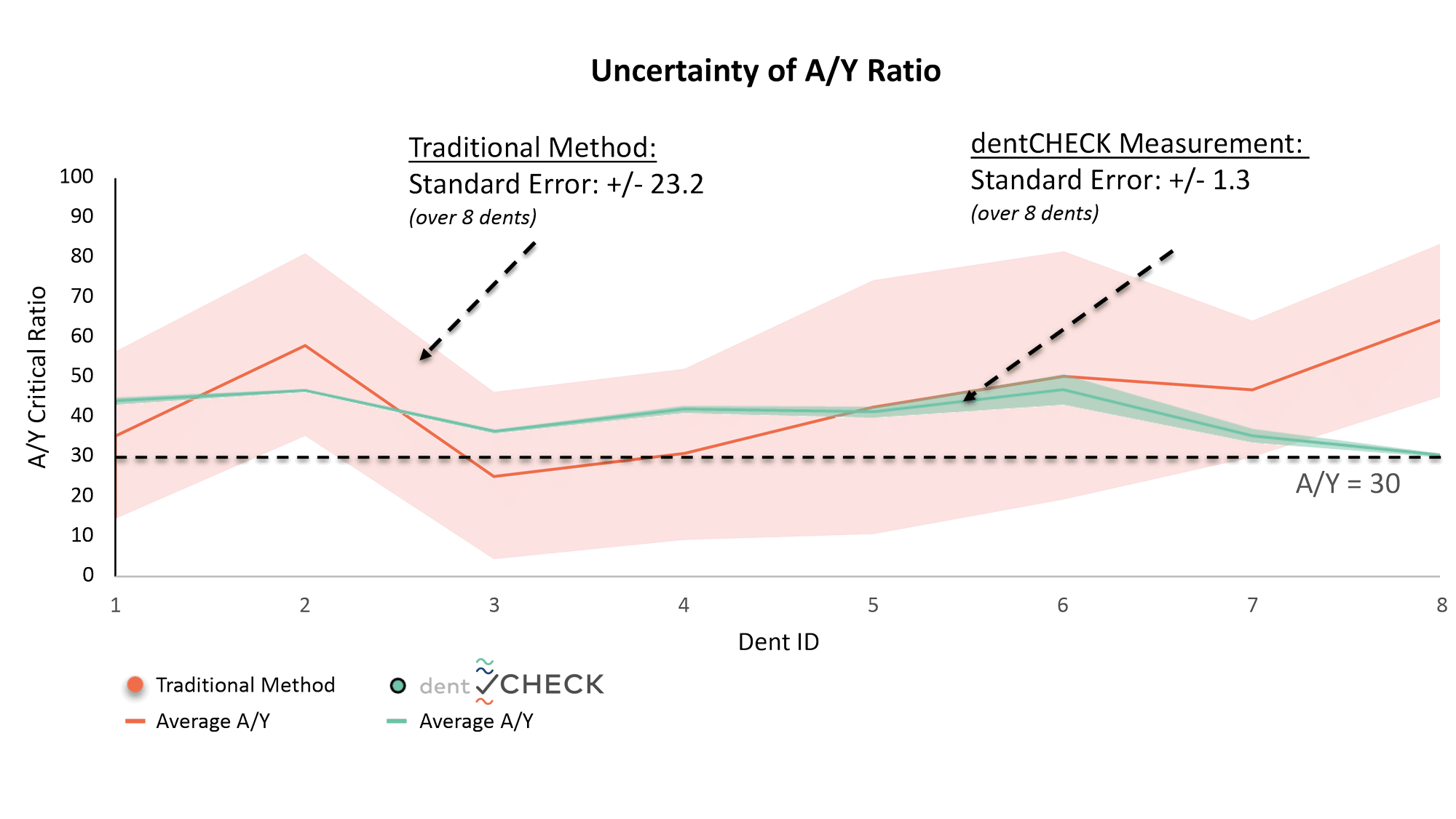

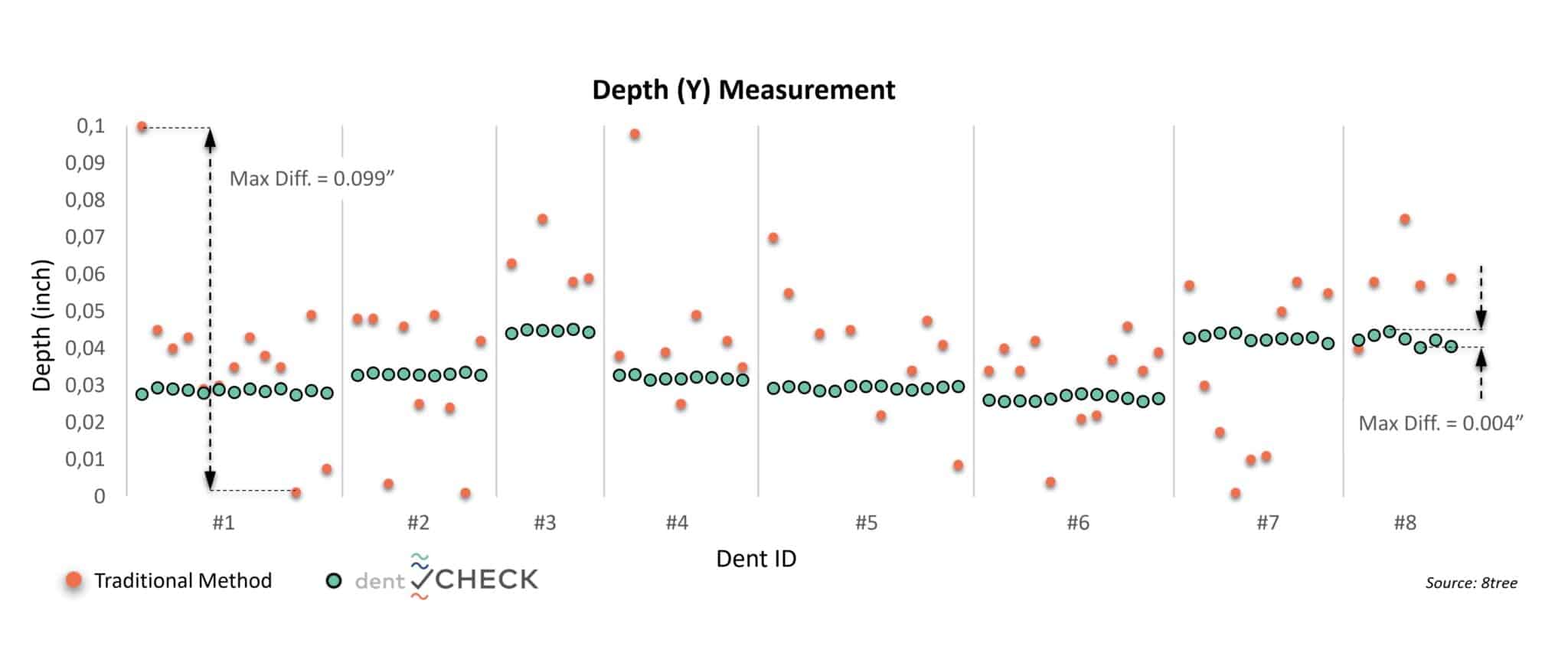

With this vision in mind, 8tree makes 3D optical surface inspection tools that solve chronic problems for multiple industries – including dent-mapping for aviation. 8tree’s products empower every operator – from mechanics on the floor, to engineers in the lab – with actionable precise measurements, portability and performance. With its patented user-centric product design and instant ‘go/no-go’ answers, 8tree is committed to making precision 3D scanning more broadly accessible – technically and commercially.

For recent news follow 8tree on LinkedIn.

8tree is proud to announce 8cloud

8tree is proud to announce 8cloud